rMIX: Production of Bagging Machine with Vibration on Polymer Production Line

rMIX: Production of Bagging Machine with Vibration on Polymer Production LineCode: 10407. We produce a series of automatic or semi-automatic, vibrating bagging machines for bagging polymers. Thanks to their small size, the bagging machine is perfectly suited to direct filling from extrusion plants : the granules can be introduced directly into the bags from the pelletizing system, if combined with a hopper loading system or other devices for transporting the granules. This bagging machine was developed to manage filling on extrusion lines up to 300Kg per hour ; the operator can hook the empty bag to the device and then dedicate himself to controlling the extrusion system, allowing the progressive filling of the bag in real time. As soon as the bag reaches the set weight, the feeding system stops, allowing a new bag to be placed. This solution is optimal for small-sized productions that require a bag change 5-6 times an hour. Origin: England Category: Plastic machines - automatic bagging machine - vibrating - polymers If you are subscribed to rMIX contact the company, if you are not, subscribe by choosing the contract you prefer .

SEE MORE

rMIX: We produce a line of pelletizers for plastic polymers

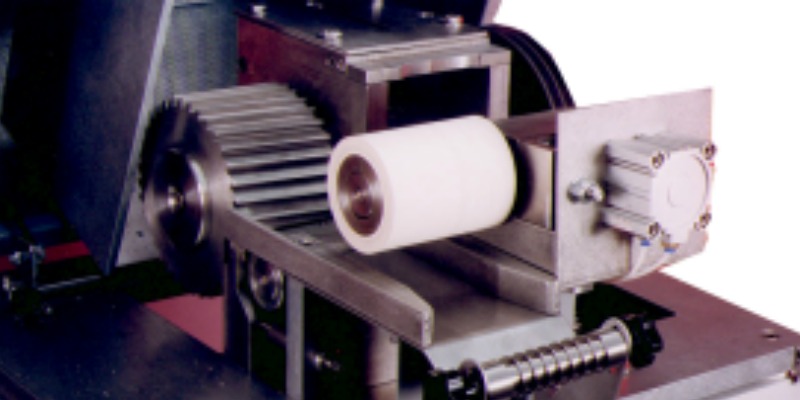

rMIX: We produce a line of pelletizers for plastic polymersCode: 10406. We produce a complete line of pelletizers for plastic polymers suitable for the production of recycled or compound granules. Our plastic polymer pelletizer, featuring a dry cutting mechanism with capacity for 20 filaments and a 100mm feed mouth, has been designed to maximize the efficiency and flexibility of the pelletizing process. The large rotor, mounted on a cantilevered axis, facilitates unprecedented accessibility to the internal components of the cutting chamber, significantly simplifying cleaning operations and allowing rapid process changes , essential for adapting to variations in color or type of polymer. A notable innovation of this pelletizer is the ability to replace the feed rollers and rotor without the need to dismantle the bearings , thus reducing machine downtime and increasing operational efficiency. We offer the pelletizer in two drive configurations: a single-motor version equipped with a gear shift, which ensures consistent, high-precision cutting of the pellets, and a dual-motor version, which offers the flexibility to electronically adjust the length of the pellets . Origin: England Category: Plastic machinery - pelletizer - polymer cutting - extrusion If you are subscribed to rMIX contact the company, if you are not, subscribe by choosing the contract you prefer .

SEE MORE